Technology Highlights of 3D Metrology Inspection Service

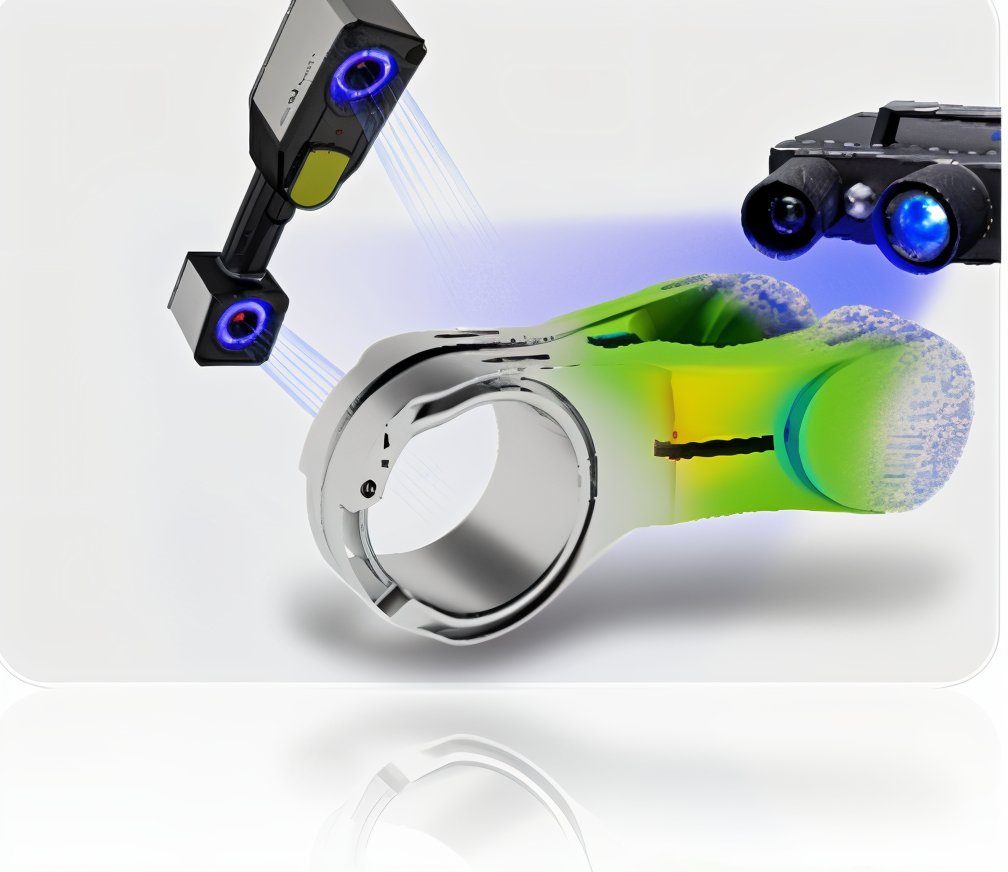

Using advanced ZEISS scanning systems and GOM Inspect software, we generate detailed dimensional analyses, CAD comparisons, and inspection reports to validate design intent and uphold high-quality standards.

Dimensional & GD&T Inspection (take the LS image) – Our team performs detailed dimensional analysis and geometric dimensioning & tolerancing (GD&T) checks to ensure conformance to design intent.

- • CAD-to-scan comparison for deviation analysis.

- • Feature-based inspection (datums, holes, slots, surfaces, etc.)

- • Real-time deviation colour mapping and inspection visualization.

Digital Reporting & Data Analysis- Our detailed reports provide a clear visualization of inspection results for quick decision-making.

- • 3D deviation colour maps.

- • Custom templates for customer-specific standards.

- • PDF and interactive 3D report formats.

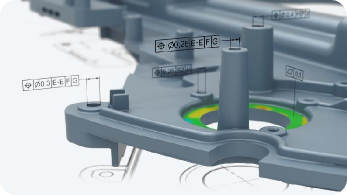

2D Inspection & Measurement Extraction (take RS image) – We extract 2D measurement data directly from 3D scans or CAD models to support drawing-based validation.

- • Generation of inspection drawings

- • Measurement of cross-sections, dimensions, and tolerances

- • Supports legacy 2D documentation processes