About 3D Reverse Engineering:

Unlock Innovation and Cut Costs with Precision Reverse Engineering

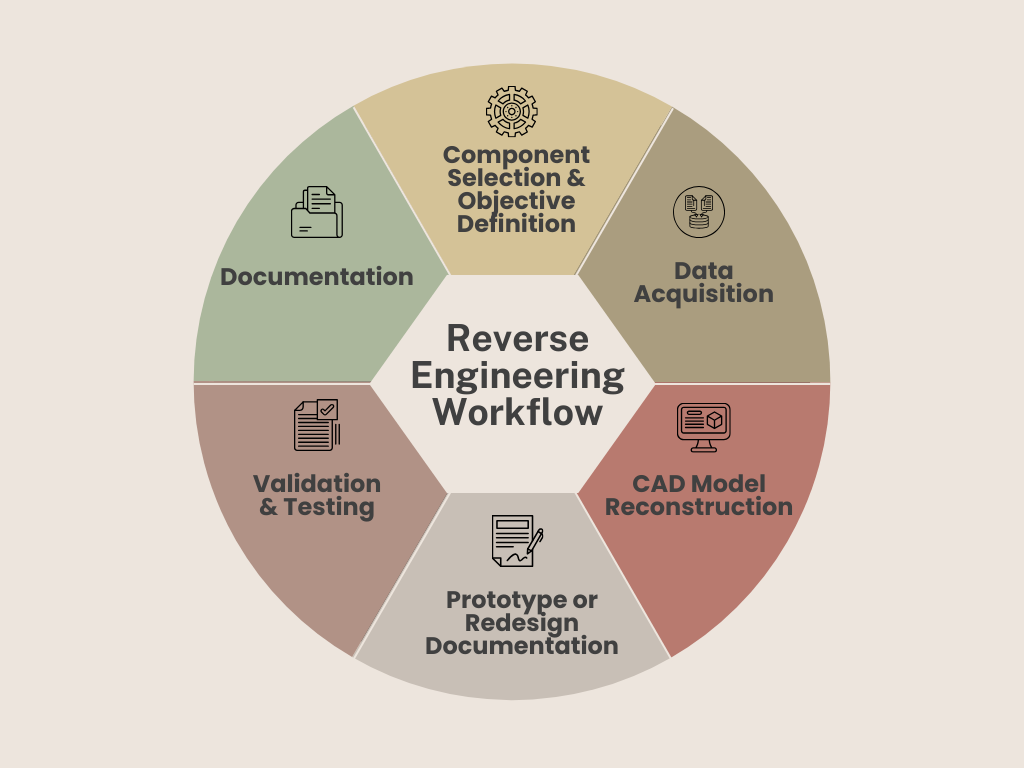

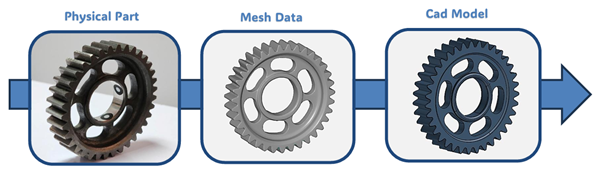

Reverse engineering is a strategic process that enables manufacturers to analyse and recreate existing products—especially legacy components—by extracting design intent and technical specifications from physical parts.

This approach supports legacy part reproduction, design recovery, and tooling or mold recreation, helping companies maintain continuity even when original documentation is unavailable.

It also plays a vital role in quality control and inspection, ensuring dimensional accuracy and material integrity throughout the product lifecycle.