About 3D Scanning:

Accelerate Accuracy with 3D Scanning Services

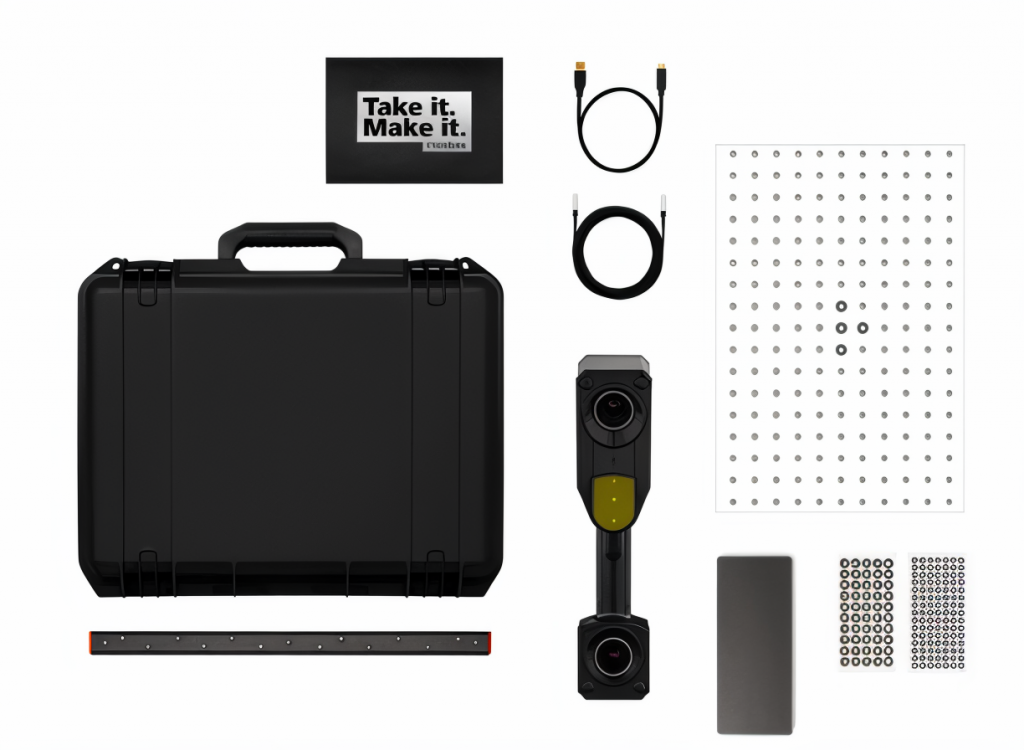

3D Laser Scanning is an advanced non-contact measurement technology that captures the precise geometry of physical objects.

Non-destructive 3D measurement method uses laser lights to capture the Shape, Size, Geometries and Texture of physical objects.