About Material Testing:

Enhancing material characterization through high-precision 3D metrology for structural integrity and performance validation

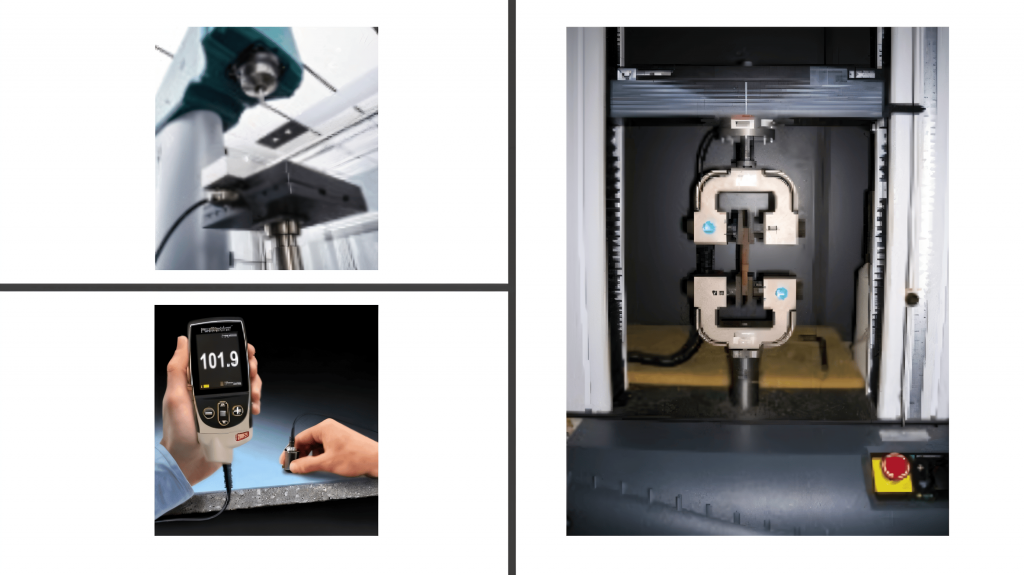

Material Testing is the process of evaluating the physical, mechanical, and chemical properties of materials (like metals, plastics, composites, etc.) to determine how they will perform under different conditions such as stress, heat, load, or pressure.

It helps engineers and manufacturers understand how a material behaves — whether it is strong enough, durable, flexible, or suitable for a specific application.