A Quick Introduction to the Creo Behavioral Modeling Extension

Let’s look at three common scenarios that cause engineers and designers to waste time and develop products that aren’t as good as they could be.

Iterating:

You probably know that most designs start with design requirements. These may specify weight, volume, center of gravity, clearance, surface quality, motion, and even custom calculations. To find a solution that meets these requirements, you must often perform tedious and time-consuming iterations. To find an acceptable solution, you’ll modify a model, perform measurements, and then repeat… over and over and over again.

Iterating some more:

Once you find a solution, the design must be optimized to find the best possible solution. If you design consumer electronics, how much would a 5 or 10% weight reduction translate to increased customer satisfaction? If you work in aerospace, what effect would that have on vehicle performance? For many products, lower weight means less materials, and therefore lower material costs. Finding this “best possible design” requires substantial time and effort spent iterating and analyzing potential model solutions.

Making tradeoffs:

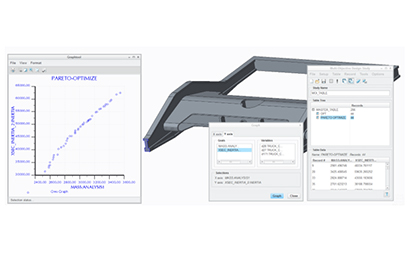

If you have conflicting and competing qualities that you’re designing toward, how do you perform trade studies? Can you generate high numbers of experiments and select the best results?

Introducing BMX:

Why not let your CAD software find the answers for you?

The Creo Behavioral Modeling Extension (BMX) solves these three problems:

- Driving your model toward specified requirements.

- Optimizing your designs.

- Performing trade studies.

How does BMX accomplish this? With the following options:

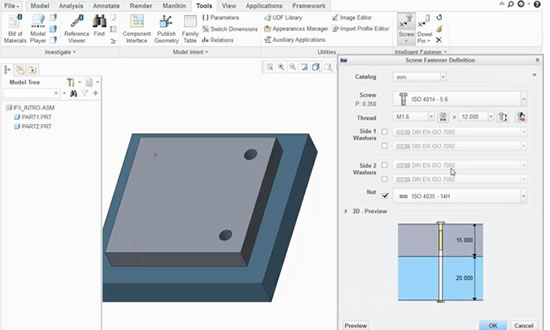

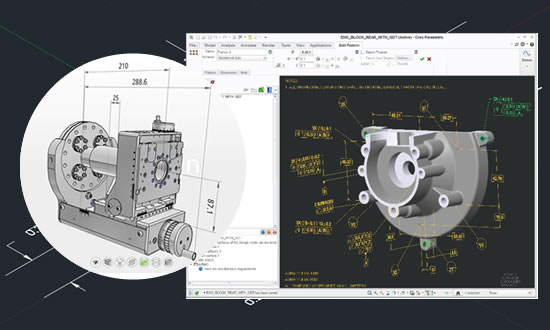

Datum Analysis Feature performs calculations and measurements on your model and then generates parameters and other datum features. For example, you can create a parameter for the model’s mass and locate a coordinate system at the center of gravity.

User-Defined Analyses can incorporate construction features to perform a custom calculation over a domain.

Excel Analysis links your models to excel spreadsheets and Prime Analysis links your models to PTC Mathcad Worksheets to drive your model from engineering calculations.

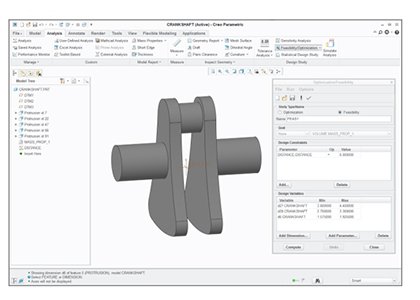

Feasibility Studies iterates model dimensions you select within specified limits to find a solution that meets the constraints you specify. For example, you could:

- Drive your model to the interior volume you desire.

- Locate the center of gravity where your model will be most stable.

- Specify the desired surface characteristics such as dihedral angle (for tangency), Gaussian curvature (for aesthetics), or radius (for ability to thicken).

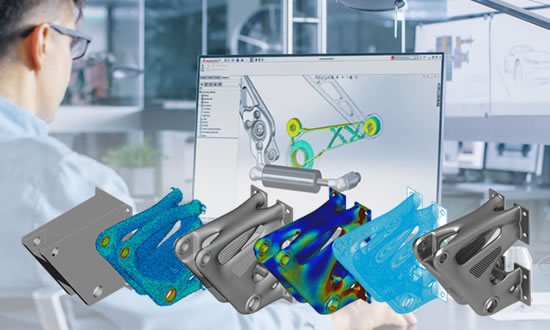

- Optimization Studies find the best possible solution for a feasibility study by maximizing or minimizing some measured parameter (such as mass).

- Multi-Objective Design Studies allow you to generate experiments for conflicting design constraints, and then pare down the results to find solutions that meet the right balance.

Example of a Multi-Objective Design Study where we aim to increase Moment of Inertia while reducing mass.

With BMX, you build your design intent directly into your model. In fact, BMX is the ultimate in feature-based parametric modeling, because you create features in your model that ensure that changes to geometry will update the rest of your model so you meet your design constraints and goals .

To know more join our upcoming webinar on 22nd Of May’19 from 3:00PM to 3:30 PM by our Tech Expert.

Click here to Register Now