Custom Application & Design Process Automation on Die & Tooling industry

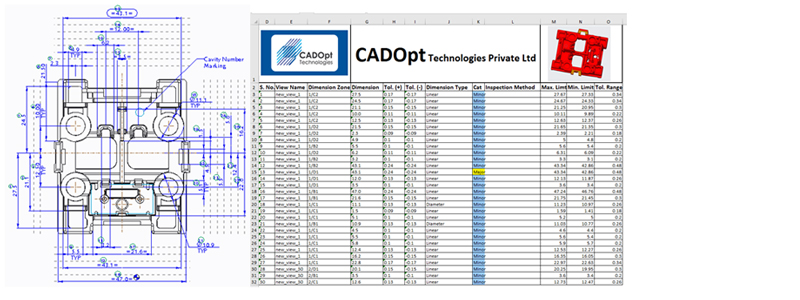

Inspection Report is an add-on application developed for Creo (Pro/ENGINEER) that automatically collects, manages and documents characteristics from Creo (Pro/ENGINEER) for the Inspection process. It collects all type of dimensions (d#, ad#, add#, dd#), Geometric Tolerance & Annotation note and it’s details from Creo (Pro/ENGINEER) drawing file irrespective of the way it is created (from 3D Model / 2D Drawing) and displays it in a MS Excel file and also creates a balloon in the Creo (Pro/ENGINEER) Drawing file.

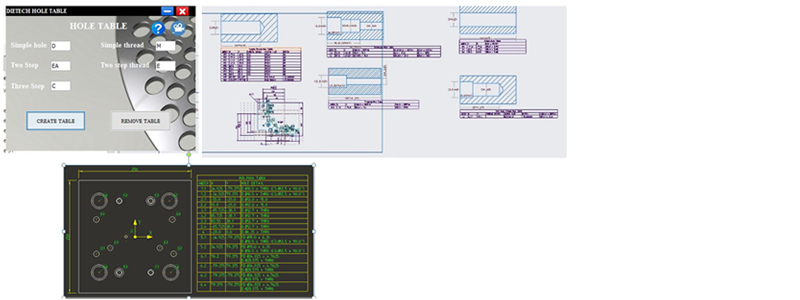

ADVHole Table Application

ADVHole Table Application is another add-on application developed for Creo (Pro/ENGINEER) that automates all aspects of creating, updating and maintaining drawing hole tables in Creo 2D Drawing application/module. It utilizes geometry-based feature recognition to identify any type of revolved (Cylindrical / Conical) feature, regardless of the way it is created I.e.. a Hole may have been created by any Cut/Hole/UDF/Sketch type features. This application extracts all the Hole information and displays it in a neatly arranged customized table/report.

Costing Report Application

Costing Report Application is an application developed for Creo (Pro/ENGINEER) that automatically collects, manages and documents BOM information from Creo (Pro/ENGINEER) for the Costing process. It collects all type of information like part, material, quantity, mass properties alongside cost and displays it in a MS Excel file.

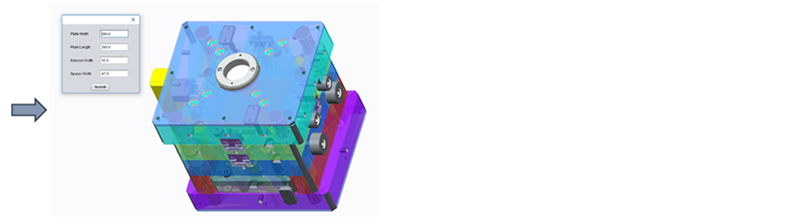

Mold Base Size Tuning

Mold Base Size Tuning is an embedded tool inside Creo (Pro/ENGINEER) for adjusting the size of the mold base and respective components pitch with respect to wall thickness maintained for each element in Expert Moldbase Extension (EMX). This allows the users to update mold base and sizes even in the last stage of tool design and maintain constant pitch values of components while varying the sizes.

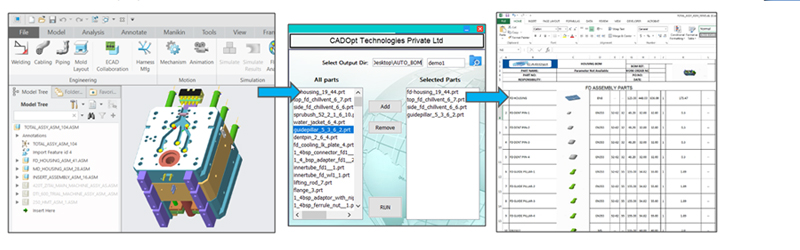

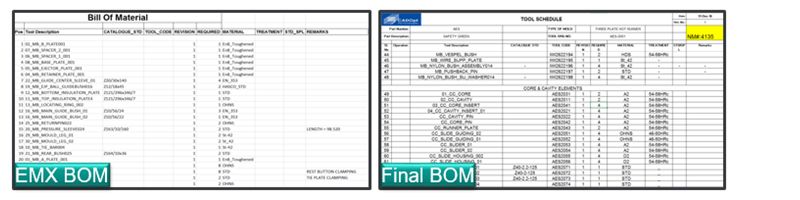

EMX-BOM Report

EMX-BOM Report is an embedded tool inside Creo (Pro/ENGINEER) for converting BOM output from Expert Moldbase Extension (EMX) into Customer Standards. This converts the data from the EMX Excel into Customer Standards and also it fills the Tool code according to part name and Treatment value according the material assigned. The attributes of the BOM (like Revision, Quantity… etc.) will be pulled from the part parameter. It allows the user to Change the attributes directly in Excel and import that to Creo. This App also fills the title block of BOM from the top level assembly parameters.

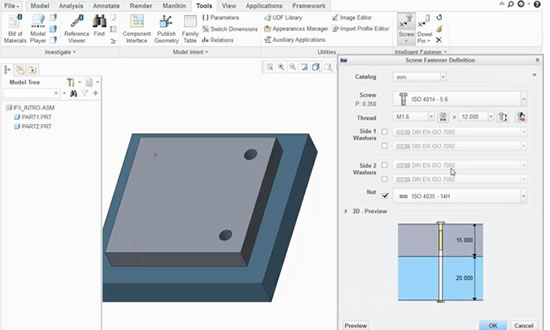

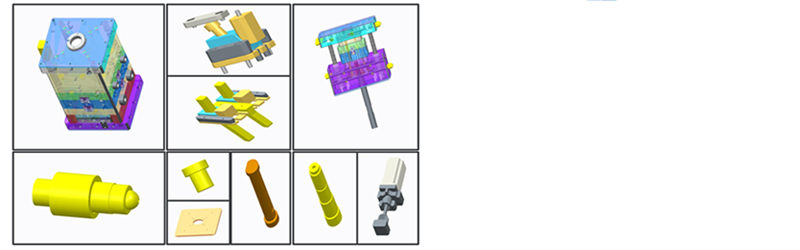

EMX Library Customization

EMX Library Customization makes the users to use and retrieve their company Standard components and Mold base. Components like Mold leg, Assembly tie bar, Frictional puller, Limit Bolt assembly, Cam pin slider, Dog leg Slider… etc. and Standard Mold base (2 plate, 3 plate, Baby Mold with their respective variants) are created. Screw Hole sizes, Ejector cut-outs and Part Names assignment with respective to their category have been customized to customer needs.

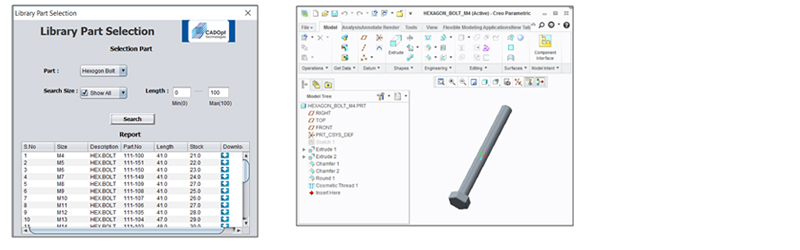

Library Part Selector

Library Part Selector application will help the users to search/select the available Standard parts from library & download the same to the workspace