Additive manufacturing (AM), also called 3D printing, is a method of creating physical objects layer by layer. Hobbyists and manufacturers alike have embraced AM because it can produce one-off objects without the upfront time or expense that high-volume manufacturing requires. In fact, it’s been especially useful for producing prototypes to test designs. Some also find AM helpful for creating hard-to-find replacement parts (think vintage cars).

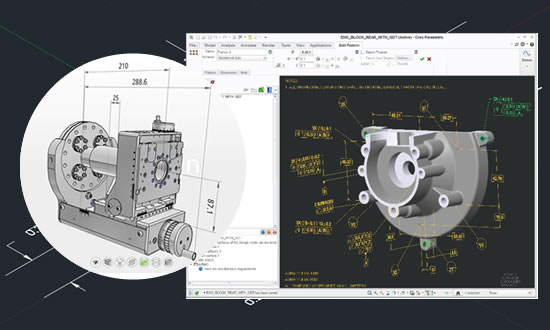

Additive manufacturing builds up thin layers of plastic to create an intricate 3D object, guided by a 3D CAD model.

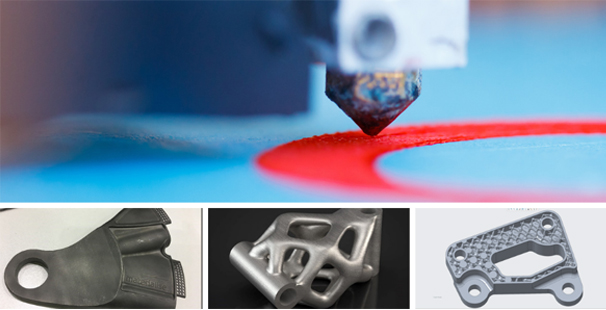

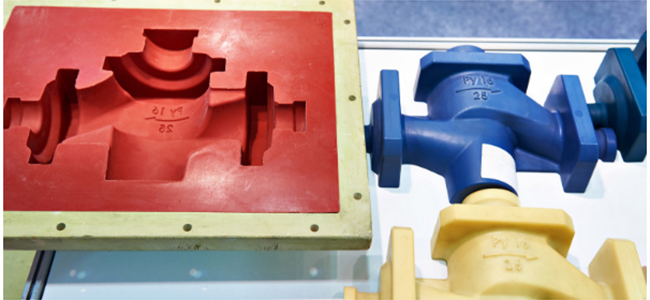

Injection molding creates parts that may cost pennies to produce. Unfortunately, setting up the mold (left) and other manufacturing steps are cost-prohibitive if you only need a single copy of a part.

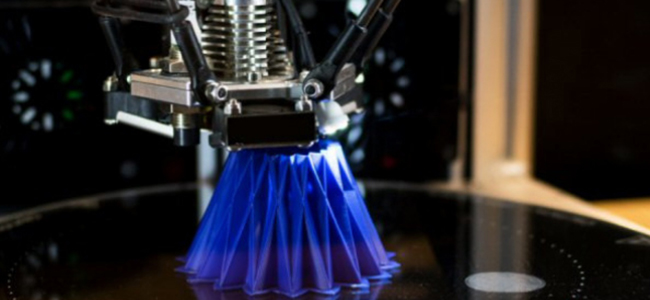

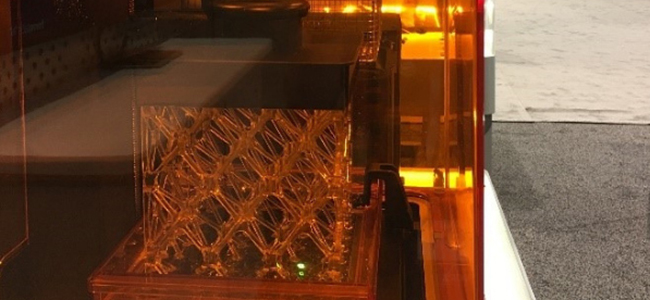

A stereolithography machine uses ultraviolet light to harden (cure) layers of photosensitive polymers.

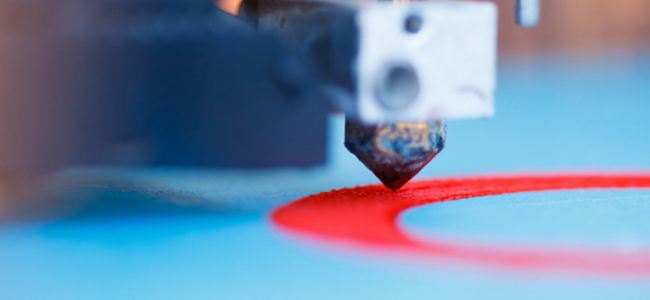

A printer applies the first layers of a curved object.

How Additive Manufacturing Works

Think about how you print a letter on your laser printer. You print one line. Another line below that. Some more lines. Eventually you printed your entire letter and then send it to your great uncle Fred who doesn’t use email (let alone text or Snapchat).

Similarly, additive manufacturing starts with a base layer of material. Next comes a bunch of middle layers. And, eventually you print the final layer and your object is complete.

This often looks something like a robot with a glue gun, applying hot plastic to a platform. But note there are dozens of other ways of precisely layer material. For example, laser sintering is a form of additive manufacturing that uses light to fuse particles together in a powder bed.

No matter your approach, once the print job is complete, you remove the 3D object from the printer, clean off supporting and other vestigial materials, and apply whatever finishing steps you want (i.e., sanding or painting). Or, you can just grab it and use it!

A metal part created by additive manufacturing

Beyond Prototypes

Why doesn’t everyone use AM? The truth is that it may take hours to finish an object. That’s fine in the development lab, but it doesn’t scale for big jobs. For example, once everything is in place for injection molding, it can deliver a single part in seconds—which is helpful if you need to deliver 100,000 widgets by Christmas. And for precision (think medical applications), computer-guided CNC milling might be more accurate.

That said, many design shops and manufacturing companies already have a 3D printer, or several, on site. Others may work with companies that print objects from their 3D CAD design and mail the part back, sometimes overnight.

CAD Meets Artificial Intelligence

There’s one more thing you should know about additive manufacturing. It’s about to change the world.

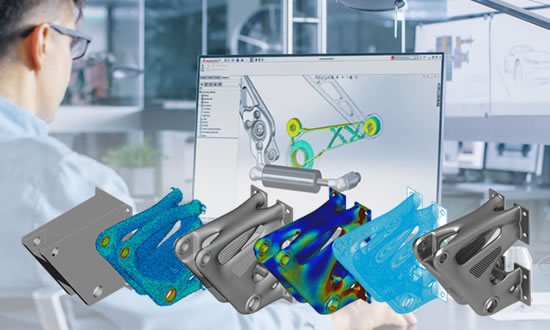

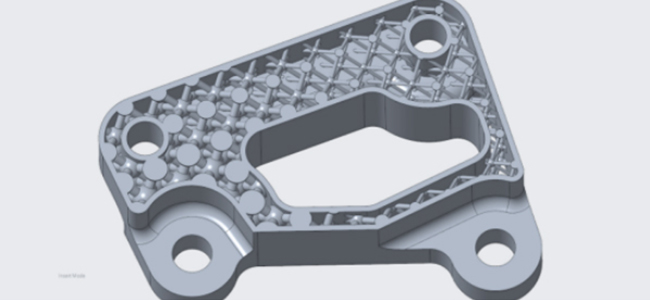

This model made of lattice structures would be nearly impossible to produce with a mold or milling machine.

Newer 3D printers now use metal, ceramic, nylon, concrete, and more. And It’s a super flexible method that can produce objects not possible with traditional manufacturing. And when you combine it with other innovative new technologies, such as generative design, it opens a whole new world of design possibilities.

Generative design uses artificial intelligence (AI) to suggest design options to product developers. Engineers simply define objectives and constraints for a model, and the software shows them the best designs that meet those requirements. So, in a way, robots are now partnering with designers to create your next tea pot or wind turbine or space station.

The end result can be optimized for any fabrication technique, including additive manufacturing. Imagine a world full of organic, sophisticated shapes that meet critical design specs with machine-like efficiency—and look nothing like what you’ve seen before.

Artificial intelligence helped design this object to provide strength, without any unnecessary weight (or material). The fastest way to take it from CAD system to real world? Additive manufacturing.

Optimize Your Additive Manufacturing Process with Creo

Hopefully this demystified additive manufacturing and convinced you to give it a try. Are you ready to shorten your product development process and make the impossible, possible? Check out the eBook Top Reasons to Design with Creo to find out even more about the CAD innovations that are reinventing engineering and manufacturing today.